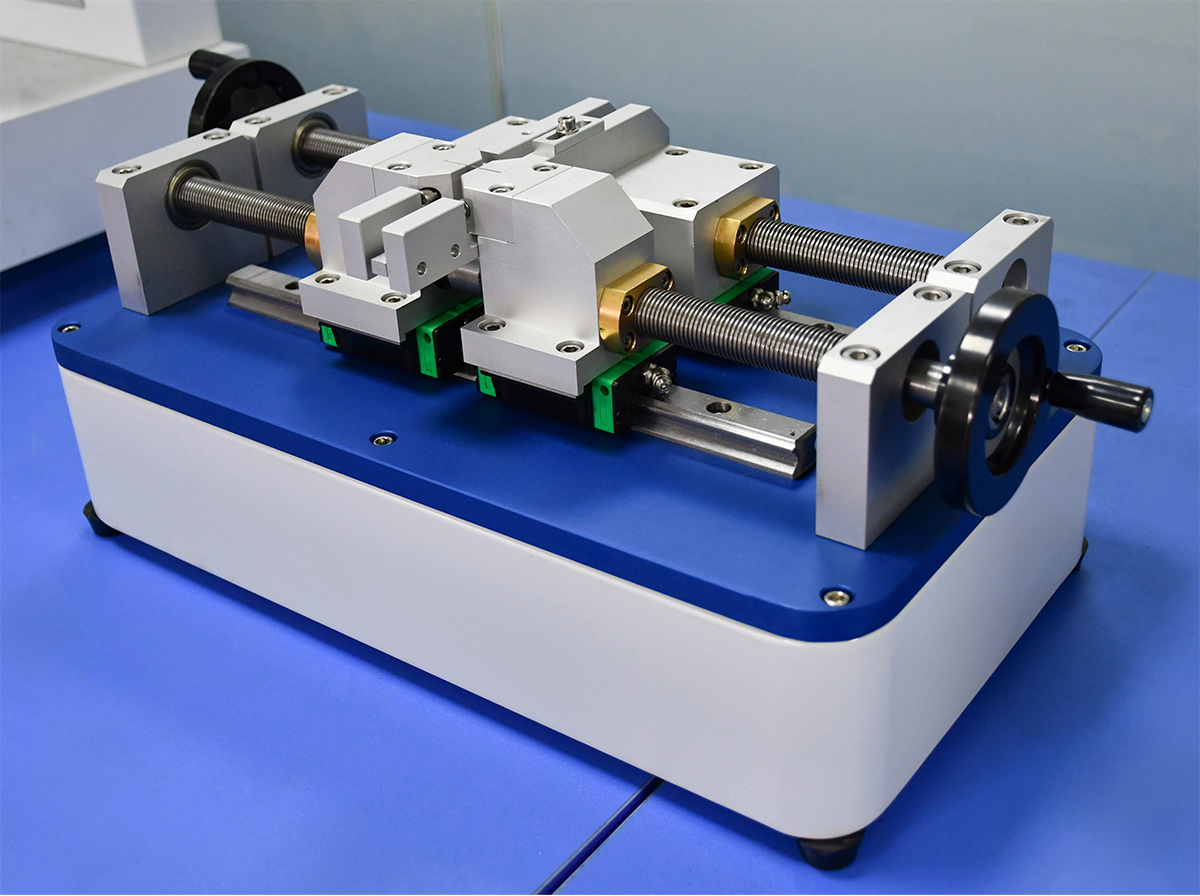

Double notch prototype

First, product overview

The prototype adopts a unilateral knife with a thickness of 0.23±0.03mm and a cutting Angle of 14°±2°. Notch is processed on both sides of the sample to prepare the standard notch sample. It is suitable for double-notch sample preparation of high molecular weight polyethylene (PE-UHMW) molding materials and thermoplastic pipes. Easy to measure the double notch impact strength of simple supported beam. It can also be used for notch preparation of FNCT and PENT samples. It is a necessary instrument for making double-notch samples of various testing institutions and polymer research units.

Second, meet the standard:

GB/T 18743.1-2022 thermoplastic pipe simple beam impact strength determination - Part 1 General test method

GB/T 18743.2-2022 - Determination of impact strength of simply supported beams of thermoplastic pipes - Part 2

GB/T 21461.2-2008 Plastic ultra-high molecular weight polyethylene molding and extrusion materials - Part 2 Test conditions for pipes of different materials

ISO16770 plastic polyethylene - Determination of environmental stress fracture (ESC)

ASTM F 1473 Standard test Method for notched tensile tests for measurement of Slow Crack Growth Resistance of polyethylene pipes and resins

GB/T 21461.2-2008 Plastics - Ultra-high molecular weight polyethylene molding and extrusion materials - Part 2

Third, the instrument features:

The machine adopts two-way T-screw adjustment pattern and feed, double knife cutting, moving and moving distance equal, radial no deformation, reduce the human error caused by movement, the blade is embedded, the whole blade only cutting head exposed, the tool body and fixed block no gap, so that the blade has no vibration, the blade has no bending, improve the coincidence accuracy of the two blades, the cutting process first tighten the pattern, Then cutting, one-time feed, double blade cutting at the same time, no need to turn over the sample, simple and convenient operation, electronic dial indicator display cutting depth, accurate and reliable numerical.

Fourth, technical parameters

Cutter thickness: 0.23mm±0.03mm cutter cutting end Angle: 14°±2°

Sample remaining thickness: adjustable clamping width adjustment range: 1mm-25mm

Cutting accuracy: ±0.05mm Overall size: length 480mm× width 230mm × height 250mm

Fifth, instrument configuration:

|

Main machine |

1 set |

|

Blade |

2 random, 2 spare |

|

Electronic dial indicator |

1 piece |

|

Allen wrench 3mm |

1 |

冀公網(wǎng)安備 13080502000095號(hào)

冀公網(wǎng)安備 13080502000095號(hào)