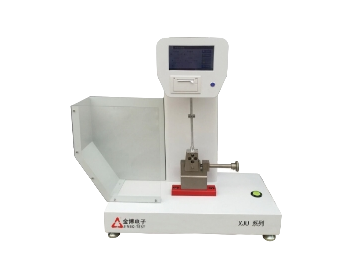

Cantilever beam impact testing machine

First, scope of application

Mainly used for hard plastics, reinforced nylon, glass steel, ceramics, cast stone, electrical insulation materials and other non-metallic material impact toughness determination. Chemical industry scientific research units, colleges and universities, quality testing departments, professional manufacturers laboratory and other units ideal test equipment.

Second, implementation of standards

GB/T 1843 "Plastic cantilever beam impact test method" IS0180-1993 "Plastic cantilever beam impact strength determination" GB/T 2611 "Testing machine general technical requirements" JB/T 8761 "Plastic cantilever beam impact test machine" ASTMD25 "Plastic impact test Method".

Third, product characteristics

The product uses color touch screen display, the operation is simple and clear. Single board computer control, stable and reliable, with energy loss automatic correction function. The automatic calculation of experimental results can be printed by micro-printer. The host can be connected to a PC to export, edit and print, and can also be connected to the notch depth measuring instrument, through the notch depth measuring instrument to accurately transmit the dimensions of the sample to the host, save the data and improve the accuracy of the experimental results. The best sample is type 1, which is the preferred type.

Fourth, working principle

Use a pendulum of known energy to impact a sample supported into a vertical cantilever beam at one time, and measure when the sample is damaged. The absorbed energy is a fixed distance from the impact line to the specimen fixture for the notched specimen, a fixed distance from the impact line to the notched center line. The testing machine should be pendulum type: and indicated by the pendulum, sample support, energy

The main components, such as the mechanism and the body, can show the impact energy absorbed during the failure of the sample. The impact strength of the cantilever beam of the unnotched sample: The ratio of the impact energy absorbed by the unnotched sample during the cantilever impact: The ratio of the original cross-sectional area of the sample is expressed in KJ/㎡. Notched sample cantilever beam impact strength: notched sample, the impact energy absorbed in the cantilever beam impact failure process and the original cross-sectional area of the sample at the gap ratio, expressed in KJ/m.

Fifth, technical parameters

|

Sample type |

long |

wide |

thick |

|

1 |

80 + 2 |

10.0 + / - 0.2 |

4 |

|

2 |

63.5 + / - 2 |

12.7 + / - 0.2 |

12.7 + / - 0.2 |

|

3 |

63.5 + / - 2 |

12.7 + / - 0.2 |

6.4 + / - 0.2 |

|

4 |

63.5 + / - 2 |

12.7 + / - 0.2 |

3.2 + / - 0.12 |

|

XJUD-5.5 Touch screen control cantilever beam impact testing machine |

|

|

Impact energy |

2.75J, 5.5J |

|

Impact speed |

3.5 m/s |

|

Pendulum pre-lift Angle |

150 |

|

Impact the blade to the distance above the jaws |

22mm±0. 2mm |

|

Striking center distance |

335m |

|

Blade fillet radius |

R = 0.8mm + / - 0.2mm |

|

Energy loss |

1.0J <0.02J; 2.75J <0.03J; 5.5J <0.03J |

|

Minimum resolution |

0. 001J |

|

Minimum resolution |

Length 700mmx width 350mmx height 850mm |

|

Space required |

Front and back 0.4m, left and right 1.5m, upper 1.5m |

|

Power supply |

100VA 220VAC 50HZ |

冀公網(wǎng)安備 13080502000095號(hào)

冀公網(wǎng)安備 13080502000095號(hào)